Pipe is a hollow

structure designed to provide an enclosed pathway for fluids to flow, usually

manufactured from cast metal or plastic. This section discusses some common methods for joining pipes and pipe ends with instruments together.

manufactured from cast metal or plastic. This section discusses some common methods for joining pipes and pipe ends with instruments together.

Tapered thread pipe

fittings

·

Thread fittings are more preferred for

smaller pipe sizes.

·

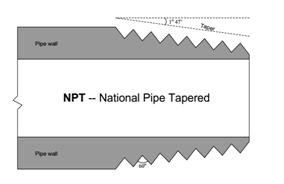

A very common design of threaded pipe

fitting is the tapered pipe thread design.

·

The intent of a tapered thread is to

allow the pipe and fitting to “wedge” together when engaged, creating a joint

that is both mechanically rugged and leak-free.

Several different

standards exist for tapered-thread pipe fittings. For each standard, the angle

of

the thread is fixed, as is the angle of taper. Thread pitch (the number of threads per unit length) varies with the diameter of pipe fitting.

the thread is fixed, as is the angle of taper. Thread pitch (the number of threads per unit length) varies with the diameter of pipe fitting.

The most common tapered

thread standard for general-purpose piping is the NPT, or National Pipe Taper

design. NPT threads have an angle of 60° and a taper of 1°47’.

NPT pipe threads must

have some form of sealant applied prior to assembly to ensure pressure tight

sealing between the threads. Teflon tape and various liquid pipe “dope”

compounds work well for this purpose. Sealants are necessary with NPT threads

for two reasons: to lubricate the male and female pieces (to guard against

galling the metal surfaces), and also to fill the spiral gap formed between the

root of the female thread and the crest of the male thread.

Another tapered-thread standard is the BSPR, or British Standard Pipe Tapered. BSPT threads have a narrower thread angle than NPT threads (55° instead of 60°) but the same taper angle 1°47’.

Parallel-thread

pipe fittings

·

One popular parallel-thread pipe

standard is the BSPP, or British Standard Pipe Parallel.

·

Like the BSPT (tapered) standard, the

thread angle of BSPP is 55°.

·

Sealing is accomplished by means of an

O-ring which compresses against the shoulder of the matching female fitting:

No comments:

Post a Comment