1. Make

sure you have Wago Ethernet Setting, WAGO-IO-CHECK, Codesys V3.5 installed in

the PC.

2. Check your PC’s IP address by going to Control Panel àNetwork and Internet.

3. Now open Wago Ethernet Settings and press

“READ”. It will display the connected PLC if the controller IP address is in

same segment.

5 Open WAGO-IO-CHECK.

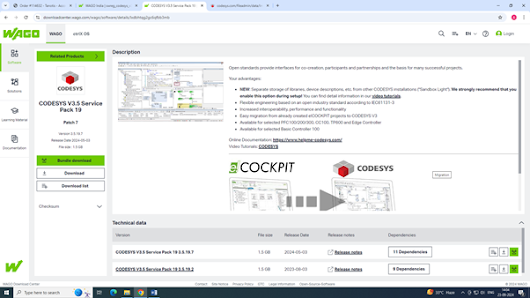

8. I encountered problem when selecting

Cockpit as Runtime System, so I selected Codesys V3. It worked for me.

9. Now

ping the PLC IP address using command prompt and it should reply. Also check

using WAGO-IO-CHECK to identify the PLC and its modules.

10.

After successful ping and device

identification, launch Codesys. Once Codesys is launched, create “New Project” à

Standard Project and save it to a desired location in computer.

11. Select

suitable Target. If no PLC is connected and user want to run in Simulation

mode, select “CODESYS Control Win V3” from the dropdown menu. I have 750-8212

connected.

12.

Then do a Gateway connectivity

confirmation. Put PLC IP address if needed. When both the LEDs are green, it

means connection is successful.

14.

The above error means the application must

be logged in.

15.

After that scan for device and it should

show the connected IO modules. Select “Copy All Devices to Project”.

16.

Once the devices are added to project, do

K-Bus mapping.

17. Write

your first PLC program.

The steps followed may work even if after slight difference in sequence.