A load cell is a transducer which converts force into an electrical output. They are commonly used in everyday life- measuring balance in regular grocery shop. The working of a load cell differs based on its type- hydraulic load cell, pneumatic load cell, and strain gauge load cells.

The strain gauge type load cell most popular. It is comprised of one or more strain gauges bonded to the surface of a metal structure with known elastic properties. The commonly used metal is Aluminum or SS. This metal structure will stretch and compress with applied force. Strain gauges are electrical conductor firmly attached to a film in definite pattern. The strain gauges bonded to this structure measure the strain, translating applied force into electrical resistance changes. These strain gauges are arranged in what is called a bridge circuit, or more precisely a Wheatstone bridge circuit as shown in diagram below. The force on the load cell is measured by voltage change in the strain gauge due to deformation. Strain gauge load cells offer accuracies from within 0.03% to 0.25% of full scale.

Modern load cells have 4 strain gauges installed within so as to increase accuracy. The arrangement is as shown in Figure above. Two gauges (R1 and R4) are under tension and two (R2 and R3) are in compression. When the cylindrical shaft is subjected to a force, it tends to change in dimension. Due to this resistance of strain gauges change.

When there is no load on the load cell, the resistances of each strain gauge will be the same. Under the application of force, the resistance of the strain gauge varies, causing a change in output voltage. The change in output voltage is measured and converted into readable value.

Types of load cells

There are different types of load cells for different applications. Commonly used ones include:

- Single point load cells: a load cell is located under a platform that is loaded with a weight from above.

- Bending beam load cells: several load cells are positioned under a steel structure and are loaded with a weight from above.

- Compressive force load cells: several high-capacity load cells are positioned under a steel structure that is loaded with a weight from above.

- Tensile load cells: a weight is suspended from one or more load cells.

Installation

The performance of a load cell depends on many factors. Central among these is proper installation and alignment. As such, it is important to follow the manufacturer’s recommendations carefully in order to get the best results from your device and to ensure safe and long-lasting use. These recommendations often include information on proper mounting and alignment of your load cell, appropriate fixing and fastener choice, the use of accessory mounting hardware, electronic adjuncts and calibration procedures

Four strain gauges are positioned on the load cells below at the point where the greatest deformation occurs when force is applied. The arrow is pointing the direction of force application.

Environmental effects on load cells

One special feature of load cells is that the environment in which they are used plays a decisive role – in a number of ways.

Ambient temperature

Every material changes with temperature, expanding in response to heat and contracting in response to cold. And the same applies to load cells and their strain gauges. This also changes the electrical resistance of the conductor. Yet load cells must measure the correct weight everywhere, regardless of the ambient temperature. To achieve this, a temperature compensation mechanism has to be built in load cell.

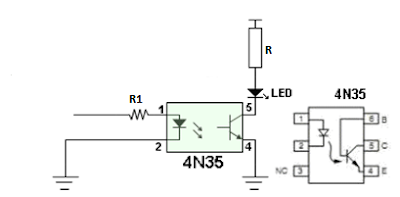

Load

cell interfacing with Arduino

With the availability

of low cost development board like Arduino, it has become easier to understand

load cell even at home. For interfacing a load cell with we will use an

amplifier board HX711 which provides 24-bit data equivalent to load. This board

is specially designed for amplifying the signals from load cells and transferring

the data to Arduino. The load cells plug into this board, and this board tells

the Arduino what the load cells measure.

We will use a 20kg load

cell for demonstration purpose. The load cells are available with 4-wires as

well as 6-wires configuration. Figure below shows 4-wire load cell which we

will use to interface with HX-711 amplifier.

|

Load cell wire |

HX-711 |

|

Red |

E+ |

|

Black |

E- |

|

White |

A- |

|

Green |

A+ |

The

connections between Arduino and HX711 module is tabulated below.

|

Arduino |

HX-711 |

|

5

V |

Vcc |

|

2 |

SCK |

|

3 |

DT |

|

GND |

GND |

It is required to

download HX711 library from Arduino IDE library manager.

Arduino code is

#include

"HX711.h"

// HX711 circuit wiring

const int

LOADCELL_DOUT_PIN = 2;

const int

LOADCELL_SCK_PIN = 3;

HX711 scale;

void setup() {

Serial.begin(57600);

scale.begin(LOADCELL_DOUT_PIN,

LOADCELL_SCK_PIN);

}

void loop() {

if (scale.is_ready()) {

long reading = scale.read();

Serial.print("HX711 reading: ");

Serial.println(reading);

} else {

Serial.println("HX711 not

found.");

}

delay(1000);

}