Electrical charges are

produced on the opposite surfaces of some crystals when subjected to force or

torsion. The electrical charge produced is proportional to the effective force.

By application of force, dimension of the crystal changes causing a

displacement of charge. Piezoelectric effect is reversible, i.e. if a varying

potential is applied to the crystal, it will change the dimension of the

crystal along a certain axis.

It must be remembered that

a piezoelectric crystal can convert a changing force into a changing electrical

signal, whereas a steady-state force produces no electrical response.

Piezo-electric crystals

are available in two forms- natural and man-made. Quartz and ceramic are

examples of naturally available piezo-electric crystals whereas Rochelle salts,

Lithium sulphate, Ammonium dihydrogen phosphate etc are examples of man-made

crystals. Quartz is considered as one of the most stable piezo-electric crystal

and is

known for its ability

to perform accurate measurement for time and frequency. Its output is independent of temperature variation. They have low voltage sensitivity but high charge sensitivity.

to perform accurate measurement for time and frequency. Its output is independent of temperature variation. They have low voltage sensitivity but high charge sensitivity.

Description of operation

The

piezoelectric effect causes a realignment and accumulation of positively and

negatively charged electrical particles, or ions, at the opposed surfaces of a crystal

lattice, when that lattice undergoes stress. The number of ions that accumulate

is directly proportional to the amplitude of the imposed stress or force.

PE

transducers use a spring-mass system to generate a force proportional to the

amplitude and frequency of the input quantity. The stress imposed upon the

piezoelectric material is the direct result of a physical input such as

acceleration, force, or pressure. To accomplish this, a mass is attached to the

crystal, which, when accelerated, causes force to act upon the crystal. The

mass, also known as a seismic mass, creates a force directly proportional to

acceleration according to Newton’s law of motion, F=ma.

Thin metallic electrodes collect the accumulated ions. Small lead wires interconnect

the electrodes to an electrical connector or feed-through, to which cabling is attached.

An advantage of PE materials is that they are self-generating and require no external power source.

A piezo-elecric crystal

can be considered as charge generator and a capacitor. External force generates

a charge and this charge appears as voltage across the electrodes.

The

voltage V=Q/C . The voltage polarity depends on the

direction of applied force.

The amount and polarity

of charge produced is proportional to the magnitude and direction of force.

Charge Q = kq

x F Coulomb, (1)

where kq is

the charge sensitivity of the crystal; C/N and F is applied force; N

From Hooke’s Law, the

Young’s modulus Y of the crystal is given as

Where A = area of crystal; t = thickness of crystal; Y = Young’s modulus; A = area of crystal;

From above equations,

The

voltage output Vo is given as

Where

C is the capacitance between the electrodes;

From above equations,

Where P = F/A= stress or

pressure, N/m2

Electrical

analysis of Piezo-electric crystals

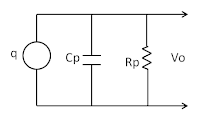

Piezo-electric crystal

can be considered a charge generator. The amount of charge is q=

kq

x F.

The charge appears

across capacitance Cp of the crystal. Rp is the leakage

resistance of the crystal. The equivalent circuit with voltage source id shown

above. The voltage

V=q/Cp = kq

x F/Cp

If a load is connected

at the output, the load capacitance CL and resistance RL

will make the loaded circuit as below.

We can consider Rp as

very large (open).

The equivalent impedance of load is

The total impedance is

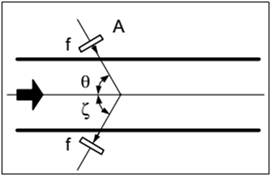

Displacement

measurement using Piezo-crystal

At steady state when ω=0,

M=0. Hence piezo-crystals are not suitable for static measurements.

Uses

They are used in numerous applications such as environmental stress

screening, vibration control, active vibration reduction, flight testing, wind

tunnel testing, structural testing, modal analysis, seismic vibration, package

testing, shock, motion and attitude detection and stabilization, ride quality

response and simulation, acoustic testing and noise, harshness and vibration

testing. Fast response,

ruggedness, high stiffness, extended range, and the ability to also measure

quasi-static forces are standard features associated with PE sensors.

Gate Questions

GATE-2008

GATE-2013

GATE-2014

GATE-2018

Gate Questions

GATE-2008

GATE-2012

GATE-2014