Introduction

A

strain gauge is a resistive sensor whose resistance is a function of applied

strain. Under the effect of external force, the length and cross-section area

of a conductor changes. Due to this resistance change takes place. The

resistivity of the conductor also changes and this property is known as the piezoresistive

effect and is expressed through the gauge factor Gf of

the conductor. The value of Guage factor is ≈ 2 for most conductors. For

Platinum its value is 6. For silicon its value is upto 150.

Early strain gauges were

fine metal filaments. Modern strain gauges are manufactured primarily as

metallic foil using the constantan or Semiconductor elements (e.g., silicon

with trace impurity boron). They are manufactured by first forming a thin film

(foil) of metal or a single crystal of Semiconductor material and then cutting

it into a suitable grid pattern. This process is much more economical and is

more precise than making strain gauges with metal filaments.

The strain-gauge element

is formed on a backing film of electrically insulated material of polymide

plastic. This element is cemented or bonded using epoxy, onto the member whose

strain is to be measured. strain

from the object must be reliably coupled to the gauge wire, whereas the wire

must be electrically isolated from the object. The coefficient of thermal

expansion of the backing should be matched to that of the wire. Alternatively, a thin film of insulating ceramic substrate is

melted onto the measurement surface, on which the strain gauge is mounted

directly. The direction of sensitivity is the major direction of elongation of

the strain-gauge element. To measure strains in more than one direction,

multiple strain gauges (e.g., various rosette configurations) are available as

single units. These units have more than one direction of sensitivity.

Gage

resistance values range from 30 to 3000 ohms, with 350 ohms being the most

commonly used.

commonly used.

Theory

The change of electrical resistance

of a material when mechanically deformed is the property used in

resistance-type strain gauges. The resistance

R of

a conductor of length ℓ and

area of cross-section A is

given by

Under the influence of tensile force F, the length of the conductor increases by dL and diameter decreases by dD

and the resistance changes by dR.

Differentiating

both sides,

where

If the change in the value of resistivity of a material under

strain is neglected, the Gauge factor can be written as

The Poisson’s ration for all metals is between 0 to 0.5. This

gives a gauge factor of about 2.

Strain gauge Applications

Many variables—including

displacement, acceleration, pressure, temperature, liquid level, stress, force,

and torque—can be determined using strain measurements. Some variables (e.g.,

stress, force, and torque) can be determined by measuring the strain of the

dynamic object itself at suitable locations. In other situations, an auxiliary

front-end device may be required to convert the measurand into a proportional

strain. For instance, pressure or displacement may be measured by converting

them to a measurable strain using a diaphragm, bellows, or a bending element.

Acceleration may be measured by first converting it into an inertia force of a

suitable mass (seismic mass) element, then subjecting a cantilever (strain

member) to that inertia force, and finally, measuring the strain at a

high-sensitivity location of the cantilever element. Temperature may be

measured by measuring the thermal expansion or deformation in a bimetallic

element.

Strain Gauge measurement

The preferred circuit for use in strain-gauge

measurements is the Wheatstone bridge. One or more of the four resistors R1,

R2, R3, and R4 in the bridge may represent strain gauges.

The output relationship for the Wheatstone bridge circuit is given by

When this output voltage is zero,

the bridge is balanced. It follows from Equation above that for a balanced

bridge,

Equation

above is valid for any value of the load resistance RL,

because when the bridge is balanced, current i through

the load become zero.

Bridge Sensitivity

Strain-gauge measurements are calibrated with

respect to a balanced bridge. When a strain gauge in

the bridge deforms, the balance is upset. If one of the arms of the bridge has a variable resistor, it can be

adjusted to restore the balance. The amount of this adjustment measures the amount by which the resistance of the strain gauge has changed, thereby measuring the applied strain. This is known as the null-balance method of strain measurement. This method is inherently slow because of the time required to balance the bridge each time a reading is taken.

the bridge deforms, the balance is upset. If one of the arms of the bridge has a variable resistor, it can be

adjusted to restore the balance. The amount of this adjustment measures the amount by which the resistance of the strain gauge has changed, thereby measuring the applied strain. This is known as the null-balance method of strain measurement. This method is inherently slow because of the time required to balance the bridge each time a reading is taken.

A more common method, which is particularly

suitable for making dynamic readings from a strain-gauge bridge, is to measure

the output voltage resulting from the imbalance caused by the deformation of an

active strain gauge in the bridge. To determine the calibration constant of a

strain-gauge bridge, the sensitivity of the bridge output to changes in the

four resistors in the bridge should be known. For small changes in resistance,

this may be determined as dVo/Vin.

Tee Rosette

Rectangular Rosette

Figure below

shows a rectangular rosette which is used when orientation of principal axes is

unknown. The gauge elements are mounted in 0°, 45° and 90° orientation. Typical setup is for each gauge element to become an

active arm in separate Wheatstone bridge circuits (i.e. a Wheatstone bridge for

each gauge element of the rosette).

Strain gauge installation

Proper

strain gauge installation is necessary to obtain accurate

experimental stress results. Skilled technicians usually install strain gauges after attending a

strain gauge school or training course. The decision on locations of the desired stress

measurements is usually made by the test sponsor or mechanical design team of the test item.

The instrumentation engineer must then ensure the following items are addressed. Failure to

proceed in this fashion will result in poor gauge adhesion, faulty data, and engineer frustration.

experimental stress results. Skilled technicians usually install strain gauges after attending a

strain gauge school or training course. The decision on locations of the desired stress

measurements is usually made by the test sponsor or mechanical design team of the test item.

The instrumentation engineer must then ensure the following items are addressed. Failure to

proceed in this fashion will result in poor gauge adhesion, faulty data, and engineer frustration.

a. The

supplies should be on hand for the technicians to apply the gauges when the

time comes.

b. The

type of gauge, the material to which the gauge is to be mounted, and the environment

in which the gauge will be exposed.

c. Are

the principal axes known (many times they are not)?

d. How

long do these gauges need to be used?

e. Will

the gauges be submersed in a liquid?

f. Will

the gauges be exposed to temperature extremes?

g. How

long will the lead wires need to be?

h. Can

the bridge completion resistors be co-located at the site of the strain gauge?

Once all

of the supplies are on hand and the desired locations of the gauges known, the installation

process can begin. The following steps should be followed.

a. Surface

preparation. The surfaces to which

the gauges are to be applied must be free of paint, oil, grease, etc. The

surface preparation usually involves paint stripping, sanding, and degreasing.

b. Install gauge or

rosette. The gauge (or rosette) is applied to

the surface with an adhesive. Adhesives exist for a variety of environments and

desired lifespan. Cure times vary from a few hours to several days. Cure

temperatures can vary from room temperature to several hundred degrees

Centigrade. During the curing process, evenly distributed pressure is usually

required on the applied gauge(s).

c. Install bridge. The

bridge completion resistor assemblies and small wire terminals or solder tabs

may be bonded near the gauge. Small gauge wire is typically used to connect the

gauge to the bridge completion packs and to the wire solder tabs. The larger

gauge lead wires are then soldered to these tabs and completion networks (not directly

to the gauge itself).

d. Epoxies and sealants.

Finally, depending on the test environment, several additional coatings of

specialized epoxies and sealants may be needed to protect the gauge(s), bridge

completion packs, and/or wire tabs.

e. Patience and skill.

Skipping steps is not advisable.

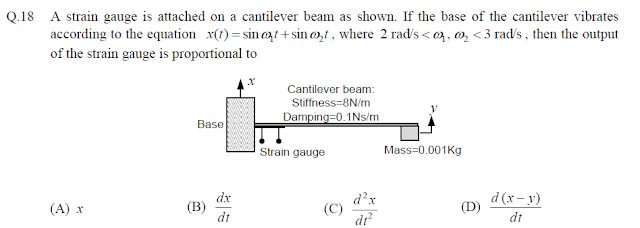

GATE QUESTIONS

GATE-2007

GATE-2008

GATE-2009

GATE-2010

GATE-2012

GATE-2014

Semiconductor strain gages typically have much higher gage factors than those of metallic strain gages, primarily due to :

(A) higher temperature sensitivity

(B) higher Poisson’s ratio

(C) higher piezoresitive coefficient

(D) higher magnetostrictive coefficient

GATE-2015

A p-type semiconductor strain gauge has a nominal resistance of 1000 Ω and a gauge factor of +200 at 25 °C. The resistance of the strain gauge in ohms when subjected to a strain of +10−4 m/m at the same temperature is __________ Ω.

GATE-2018

A 1000 Ohm strain gage (Rg) has a gage factor of 2.5. It is connected in the bridge as shown infigure. The strain gage is subjected with a positive strain of 400 um/m. The output Vo (in

mV) of the bridge is (up to two decimal places) _____.

No comments:

Post a Comment