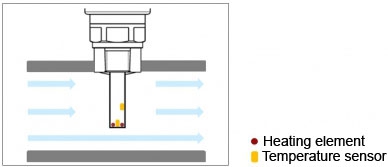

Calorimetric flow meters, as the name implies rely on calorie (heat) measurement. It is also known as thermal mass flow meter. It consists of two temperature sensors (mostly thermistors) and a heating element. One of the sensing element is constantly heated using heating element at constant power. This sensing element measures the temperature of heating element. The other sensing element measures the temperature of the medium in the pipe. The temperature difference is recorded and processed.

When the liquid flows through the pipe, it takes along the heat from tip of the probe, thus reducing tip temperature. Higher the flow velocity, more is the cooling and less is the temperature difference between two sensors.

The sensor heating can be done in two modes-

- Continuous heating mode: In this mode the heater is continuously ON because of which one thermistor is always hot and other is cold. The temperature difference which reduces with rise of flow is monitored.

- Pulsed or regulated heating mode: In this mode the the heating power is regulated so as to keep the temperature difference between sensors constant. With more flow, heating power required is more. By measuring the power, flow is calculated.

The mathematical equation governing the constant power type flowmeter is as below:

where v is the velocity of the medium, K is the calibration constant, p is the density of fluid, Ts is the sensor tip temperature, To is the medium temperature, Q is the heat supplied to heater.

Both temperature detectors (heated and reference sensor) can be connected in a bridge circuit as shown in figure above. At very low flow velocities, the bridge is imbalanced. At very low flow velocities, the bridge is imbalanced and the output signal is high. When the flow rate increases, the heated detector cools down and its temperature comes closer to that of a reference detector, lowering the output voltage.

These type of flowmeters have following characteristics:

(1) Accuracy : +/- 5%,

(2) Can measure both flow and temperature of the medium

(3) Maintenance free

(4) Easy to install. Can be mounted in any position. The sensing probe shall be completely immersed in the medium.

(5) Correction factor is required when used for liquids other than water. This is due to different thermal conductivity (k) values.